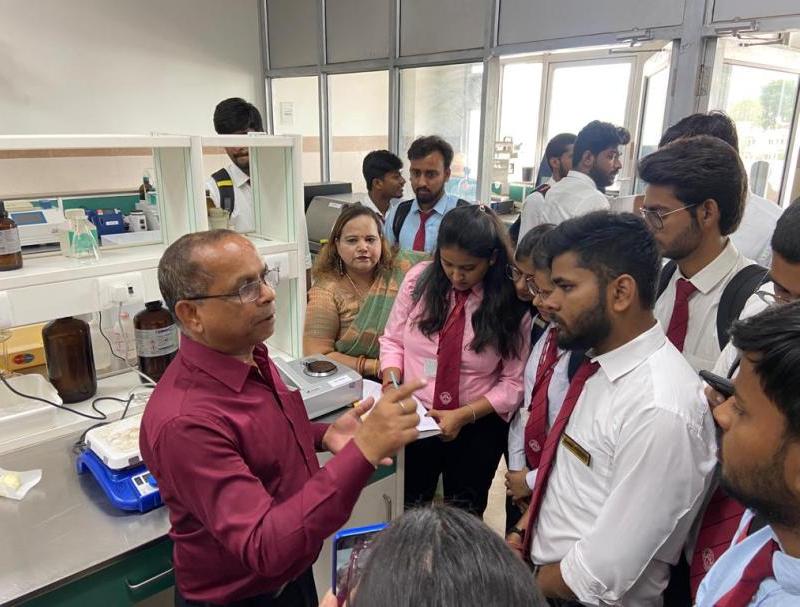

The students of #SRMSIBS (MBA and BBA) visited the new production plant of Parag at Golf City, Chak Kajehra,Lucknow,Uttar Pradesh 226002 on 25 May,2023. This visit was coordinated by Professor Dr Ekta Rastogi and headed by the manager S C Yadav and marketing associate Ranjana Chaudhary.

As per, the General Manager of Lucknow Milk Union the association was set up nearly 82 years ago. Starting out with an initial investment of ₹10 and the first-round production of 20 litres of milk, the union has made a remarkable name for it and brought glory to the city.

Established on 23 March 1938, the entrepreneurial venture grew quickly and its products became an inseparable part of the households soon. Consequently, the first plant was set up in 1963 at Jopling Road. Moreover no use of any extra chemical as preservative makes it unique and different from others. It insures safety at every step.

Having served the Lucknowites for over six decades now, the brand has become a celebrated part of the state’s local dairy industry. With the materialisation of the recent project, the milk business in the city would soon witness a boom, making ways to all corners of the country.

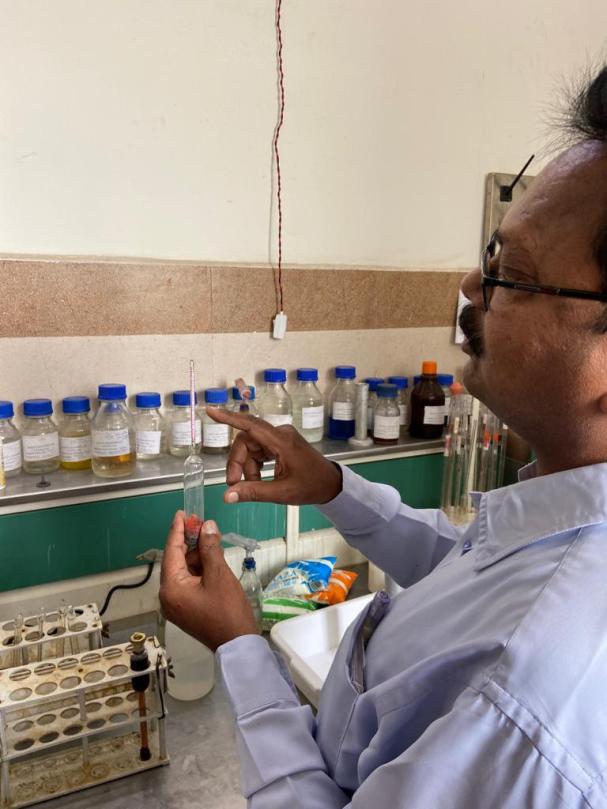

The new centre has reached a production of approximately 2 lakh litres a day.They engage in getting milk from around 450+ villages. Additionally, the plant can now manufacture 2 tonnes of butter and ghee each, 1-tonne paneer, 0.5-tonne khoya, amongst other things. Also, #ParagDairy can now offer employment to around 400 individuals and is expected to bag an aggregate turnover of around ₹150 crores. The plant is equipped with state-of-the-art machines sourced from the country and abroad, that would ensure optimum quality of milk. Amid the highlights, the plant has a censor-based densitometer that will send back milk samples which do not qualify the set standards. This innovative device presents a perfect amalgamation of German, Italian, French and Indian technologies. In addition to this, the production centre comes with automatic facilities for checking weight and quality, pasteurisation,

packing and dispatch.

It was indeed a great learning opportunity for the students to witness the live production plant fully functional and operational. Students learnt about procurement, purification, processing, packing and packaging of 25 + products produced by Parag.